Grimco’s exclusive line of Duratex foamboard gives you a quality substrate that is perfect for shorter term applications. As some of the best memory foamboards in the marketplace, the Duratex brand gives superior results at a price point you will love.

Duratex Foamboard

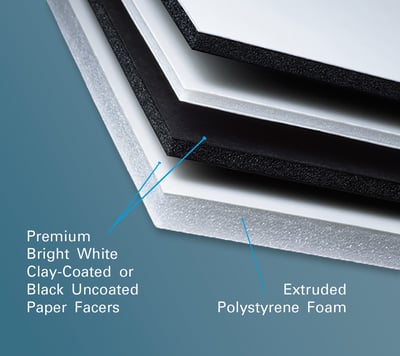

Duratex Foamboard features extruded polystyrene foam bonded between bright white double clay-coated or black uncoated paper facers, which makes them ideal for screen and digital printing applications. These boards also provide flat, smooth surfaces for

mounting graphics or backing photographs and fine art in any framing applications. These Foamboards are produced using a proprietary manufacturing process that creates a foam core unsurpassed in cutting and fabrication capabilities, and delivers superior performance in both pillowing and memory/recovery variations.

DURATEX FOAMBOARD | The Original Foam Board

- Comprised of polystyrene foam with bright white coated or black uncoated paper facers

- Provides excellent results for screen or direct digital printing applications

- Perfect for die cutting with a compressed, pillowing edge that stays closed

- Uniquely embossable for 3-D effect displays

- Extremely lightweight & cuts easily and cleanly, even by hand

Cutting Abilities

Duratex foamboards are made of recovery foam, meaning they will retain their edge profile when die cutting. This material does very well on table cutting devices as well, making it very user friendly for short-term applications.

A Non-Pillowed Edge

Duratex foamboards are non-pillowing products. So, when a cut is made the foam will still be exposed. This keeps the paper facers from compressing together and sealing. You can learn more about pillowing versus non-pillowing here.

Sizing Considerations

The Duratex foamboard comes in a variety of sizes for different applications. Board thickness impacts rigidity, making certain specs more reliable for particular applications. Michael Kerber reviewed the difference between 3/16 inch and 1/2 inch foamboard in a recent virtual tradeshow session: