When looking at plotters or cutting heads for a router, you should consider whether a drag blade or tangential blade is the cutting option best for your needs. You may know or don't have a clue which to choose. Let's break down the difference between drag cutters and tangential cutters.

Drag Blade

In the market right now, most plotters consist of drag blades. This means that the blade is in a 'fixed' position that never leaves the media surface once the cutting process begins. For most applications, this is a reliable and effective way to cut materials.

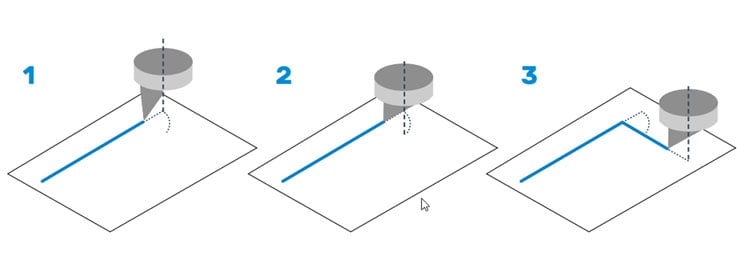

The drag blade is usually used for designs that do not require a lot of pressure, such as light boxes, billboards, window graphics, etc. It is not well-suited for rigid/thicker substrates. The movement of both the media surface and the blade combine to create a cut. Both of these movements combined allow the blade to face in the correct direction seeing as the knife can rotate freely in the blade holder.

Tangential Blade

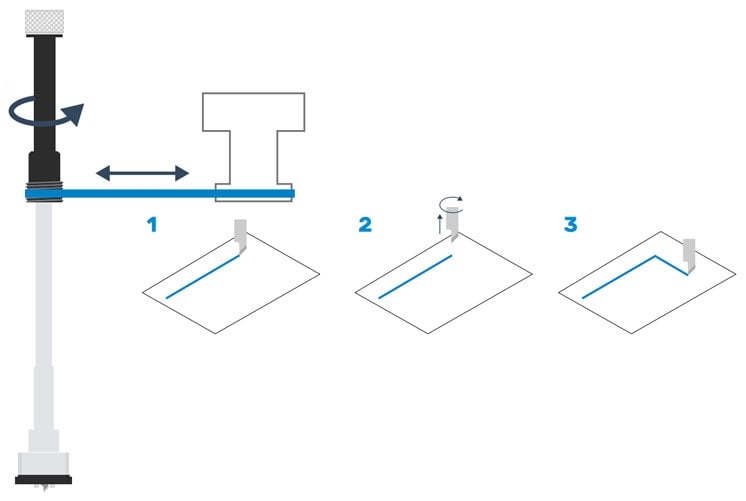

A tangential blade, however, is controlled by a motor and will actually pick up and rotate the blade. By disengaging and rotating, the blade is able to successfully cut 90 degree angles. The blade is able to cut with incredibly sharp accuracy on small text, fonts, and design, along with achieving better depth control. It is ideal to use a tangential blade for thicker, harder substrates such as vehicle and floor graphics, road and safety signs, textiles, etc.

Why not choose tangential every time? It is a more expensive technology option, and depending on your budget or the demands of your customers, it may not be necessary. For graphics producers looking to improve their current plotter, however, it’s a great option you may not have exposed to.

Summa Technology

To read further about both blade technologies and capabilities, check out Summa's page.